Like I said, I have gotten the sewing bug. And a taste for a bit of nostalgia.

Yesterday, I went to a local Joann’s and came home with a couple of really fun prints to make up some shirts / blouses. The fact is, today it is almost impossible to find any 100% cotton blouses or short-sleeved shirts for women. Almost everything is either a knit, a slimy synthetic, or a cotton blended with 3-4% spandex. The latter is really uncomfortable as far as I am concerned because that little bit of spandex takes away all the breathability of pure cotton.

This flamingo pattern caught my eye. I am a sucker for wild Hawaiian prints, and really, the worse they are, the more fun. Here in California, prints like this are totally okay, but probably not for NYC in the dead of winter. There was only 1 yard and 19 inches left on the bolt, but I took it, and got a 50% discount as it was the end of the line. From my earlier days, I used to make shirts with only 1.5 yards, so I figured I could do it. And I did, but I have put on a few pounds since my youth, and really needed a bit more for an easy layout, and while I did get it, but the neck facing was scrimped a bit.

I rummaged through my patterns, and luckily, I found this one. Short sleeves, sorta Peter Pan collar, and five easy pieces.

In keeping with nostalgia, I decided to dig out the Singer Featherweight, a 222K with the open arm, reverse stitch, and droppable feed dogs. All straight stitch otherwise. I also decided to sew this without the use of attachments, except for the buttonholer (which is later, and with trepidation), and use techniques required of a straight-stitch machine.

In some ways, I think this was actually a good choice. I always zigzag every piece before I sew it because I hate raw edges, but I could not do that with this project on this machine. In reality, I think it may be okay because the material is not constricted by the zigzagging. I did all my staystitching and edge stitching, and I clipped and layered the collar seams. In other words – I took my time!

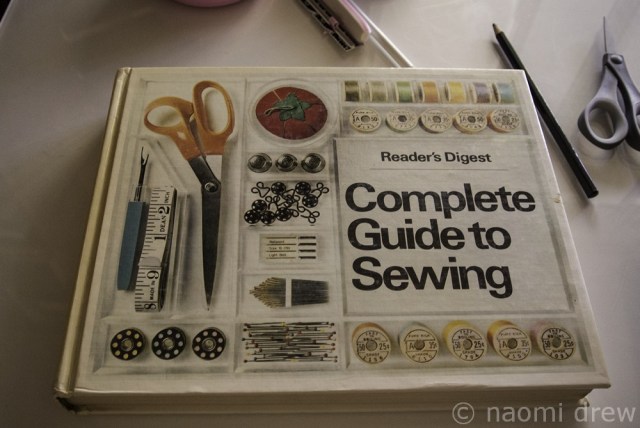

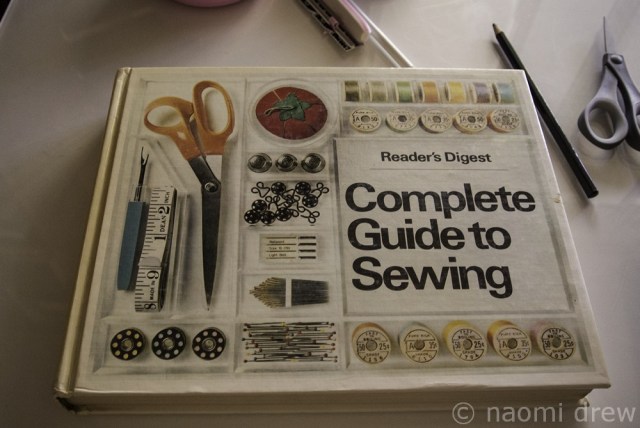

I also refreshed my sewing skills by pulling out The Reader’s Digest Complete Book of Sewing, a present from my father back in the 60s or so. Compared to more recent books on sewing, this is a real encyclopedia of information and technique; when I was younger, it was too tedious for my helter-skelter approach to sewing, but today, I really appreciated it. I read about facings and collars and edge stitching and stay stitching. I also read about using bias tape to finish edges, which I had thought about prior to the project, but learned that into a curve you do one thing, and out of a curve, you do another.

One thing I didn’t learn in my sewing classes in school was that there is a technique to put a nice point on collar – take some thread on a needle, double knot, and once you have pulled most of the collar out, run the needle into the corner on the inside, and push it through the corner on the outside, tug, and cut. A very nice point is the result! Like I said, the Reader’s Digest book is full of good information!

The blouse is far from finished, but I am fairly satisfied with my progress. It was interesting to use a straight stitch machine that is belt driven. A couple of times, the machine didn’t like the thickness of the blouse, but with some encouragement, we got through it.

What remains to be sewn are the sleeves, side seams, hem, and making the buttonholes. I am not too sure how long that will take – it may not get looked at until next Friday, because some of my days are pretty long. In the meantime, I will re-read about setting in sleeves and other good things. Nothing like a sense of accomplishment – until I destroy it with badly done buttonholes. Buttonholes are my nemesis, and I need to practice them all the time.