If you have read this blog for awhile, you do know that I have made iron gall ink on a number of occasions, as well as cut my own quills. I have tried my hand at learning Secretary Hand from the 1500s, but I never could get into it. Now, though, my iron gall ink needs replenishing, and soon enough I will get around to it – once the rains stop and I can let my galls and old wine ferment in the California sun. And, I do plan to make some red ink from sappan wood (sappen?), too, but that is for another day, when supplies show up.

I came across a recipe for ink in the form of a poem while looking up handwriting or copybooks from days of yore. It contains recipes for iron gall ink, but also ink made from lamp black (soot), which is what sumi ink is from, but also from wool! Wool?

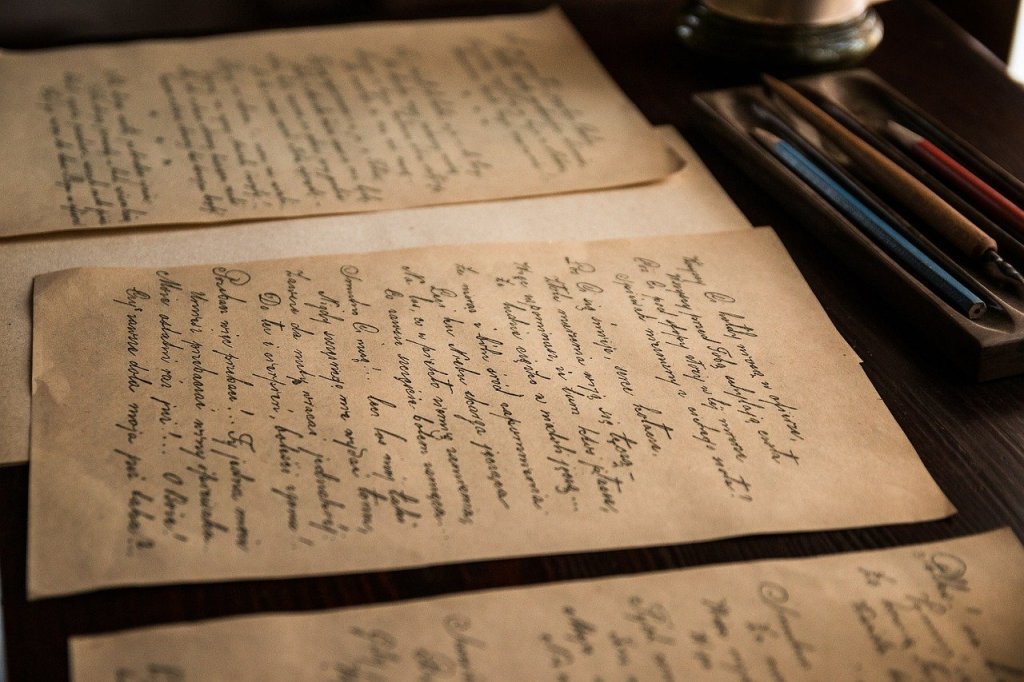

Purportedly from an English book of handwriting entitled A Book Containing Divers Sorts of Hands, by John (Jehan) de Beau Chesne (Beauchesne) and M. John Baildon, and published in 1571, here is an interesting bit of rhyme:

To make common yncke of Wyne take a quart, Two ounces of gomme, let that be a parte, Five ounces of galles, of copres take three, Long standing dooth make it better to be; If wyne ye do want, rayne water is best, And as much stuffe as above at the least: If yncke be to thick, put vinegar in, For water dooth make the colour more dimme. In hast for a shift when ye have a great nead, Take woll, or wollen to stand you in steede; which burnt in the fire the powder bette small With vinegre, or water make yncke with all. If yncke ye desire to keep long in store Put bay salte therein, and it will not hoare. Of that common yncke be not to your minde Some lampblack thereto with gomme water grinde "

I did look up this book online and found many references to it, but not a digitalized copy could be found. I would love to see it. As well, hHow correct or incorrect this poem is as far as original spelling doesn’t matter – it is rather charming, as non-standardized English spelling can be.

What is good about this poem are the specific amounts for ingredients in the iron gall recipe, which perhaps I shall try. Stale beer can be substituted for wine, and the rest has proportions which can be worked out for larger or smaller amounts. “Copras” is known as “copperas” and that is simply ferrous sulfate. “Gomme” is gum arabic. “Galles” are the oak galls.

I found it interesting that vinegar is a better choice than water to thin ink that has gotten thicker with time – evaporation I expect – as well as adding salt (in an unknown amount) to keep it from getting mouldy. Wine helps, but perhaps the salt helps even more. The wool – woll, wollen – was the new source of ink for me! Research was required, and using Google, I came across this video.

I have a feeling I am going to give this a shot, using some odd fleece I have rather than woolen fabric. It will probably be best done outdoors, as the stench could be awful and the smoke could set off the smoke detectors. It is also probably a great way to recycle your old clothes, if you are really desperate for yncke.