Where to begin? The best laid plans of mice and women can tumble away into oblivion. What once was planned is now unplanned. Chaos moves in and takes the reins. So be it.

Let us begin with yesterday. It started well enough. The Factory Dress is complete with only the need for a bit of top stitching along the front and a dab of fray check on a spot. That never happened because I set it aside for a quieter moment when I had the No. 5 open to sew a muslin (toile) for a shirt I am planning for Josh. I laid out the pattern and cut out the necessary pieces so the muslin could be basted together. But first, to be a good sewing machine owner, I determined I should oil my trusty and unrusty No. 5.

Let us begin with yesterday. It started well enough. The Factory Dress is complete with only the need for a bit of top stitching along the front and a dab of fray check on a spot. That never happened because I set it aside for a quieter moment when I had the No. 5 open to sew a muslin (toile) for a shirt I am planning for Josh. I laid out the pattern and cut out the necessary pieces so the muslin could be basted together. But first, to be a good sewing machine owner, I determined I should oil my trusty and unrusty No. 5.

I popped open the machine to access the metal parts beneath the machine itself. And pop it did. The stretchy drive band I use on it snapped. Pure hell as these stretchy bands need to be melted together with a steady flame, a steady hand, and a lot of patience.

Let’s take a time out. I will not repeat what I said.

Okay. Moving on, the melting of and mending of the drive band for the No. 5 did not take place. Attempted and failed. Thus, I oiled the lovely girl and pondered my options whilst doing so. I finally decided to try, for the second or third time, to install the traditional leather drive band, of which I have several. Historically I have tried and failed each time. To succeed at last required thought. To YouTube for what to do in order for a successful installation. This was my fortunate and happy find – lengthy, wordy, informative.

From there, it was planning and thinking. I needed to cut the leather drive band to the correct length. I needed to make a hole it the other end. Should be easy enough, but past experience showed me that the leather is hard to cut with a pair of ordinary scissors. The hole is hell to make as the rounded band rolls to and fro, escaping as you make the hole. I don’t have a drill I can use without adult supervision. And, accessing the grooved wheel is a bitch to get to. I had to plot. The under carriage of the No. 5 is a tight fit, and I am no longer my svelte and agile younger self.

In the end, it was so simple to reach the wheel I was stunned. I pulled out all the drawers on the side of The Free No. 5 to access the drive wheel. Before doing that, I was reaching inside from the knee space. Moving the machine away from the wall helped a bit, but not a lot. Removing the drawers for easy access was amazing. Click on the pictures to read the little captions below each one.

Next, inserting the drive band to wind it around the wheel to get the correct length. There is a slot in the wheel to help you guide the band around, but I didn’t do that at first. I didn’t think about it, just thought, hmm, interesting. Of course, if the manual mentions it, I don’t know as I didn’t look. Moving on, the drive band got stuck quite tightly where it shouldn’t. I had to pull and tug on it while turning the wheel. In between, I cleaned up the dust behind the machine. At least I had stretched out the drive band as recommended in the above video.

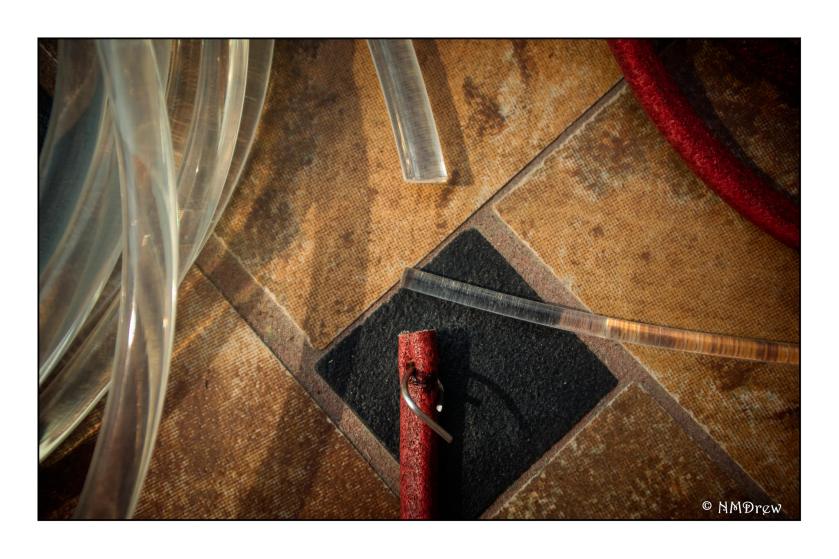

Finally loose, stretched in the machine and across my shoulders as suggested in the video, I reinserted it for the 5th time, using that nifty little groove to guide it from top to bottom and back to the top. I measured, and cut. Then, make the hole needed to join one end of the drive band with the other. A jig of wood and tape to keep the band steady, a hammer, a fine nail. All ready to reinsert, top to bottom to top, and then splice. Again, click on the pictures below to read the nifty little captions below each one.

My adventure was done. The belt was installed. My dirty floor was a bit cleaner. The splice was beautiful as I had a great pair of pliers to make a smooth cut as well as to press the wire flat into the drive band. All came together as if it were meant to be. It only took about three hours of my day, but I have emerged victorious and well educated on installing a leather drive band on a 110-year-old sewing machine.

Leather queen indeed.

An electric-powered sewing machine would have been easier, but not as much fun.

I have a 1906 White treadle machine. I’ve replaced the leather twice–in much the same fashion as your successful endeavor. The only difference was that I used a Yankee push drill to make the hole in the leather. I’ve used the nail method, but the push drill gave me great control, and remove just enough of the leather material to make the attachment easy. Bravo!

I bow to you Queen of sewing machines! And, I was just frustrated with trying to update firmware in the Fuji and a Fugi lens. Seems I need to back up my settings to a particular program. I downloaded the program but didn’t have the correct HDMI cable to get the info from the camera to the program. It didn’t come with the camera and I need to buy one! Not only will I buy one, but I’ll also let the camera store update the firmware for me. That would have been easier in the first place!

AV – thanks for the info about the push drill. I have seen such things but cannot think of a use for them in my life! So, a fine needle. Josh was busy with work, so I didn’t want to bug him. He has Dremels, and I think they may include such things. What do you sew on your White?

Anne, you may curtsy rather than bow. Gracefully please!

And I get ya as far as software updates. Seems weird to me you need an HDMI cable when a USB seems would do. Better have a knowledgeable adult do it, like my using a drill. Safer!

Not much in the past few years, since we’ve been building and establishing the garden and orchard. It’s in storage–and that has a way of slowing you down. But I made masks this year, on a little mending sewing machine that I picked up on craigslist. And most of the impending fabric projects are seat cushions for arts & crafts benches and rocking chairs.

Sounds very nice! Homemade stuff always feels good to me. 😉

I love it when people take care of history. Well done you!

Hi there! I found your blog when I was looking up John Marshall, as part of researching techniques for katazome dyeing. I studied traditional Nihonga painting in Tokyo, and apprenticed at a washi papermaking workshop in Japan for many years before coming back to the states, and now I’m trying to develop my own katazome setup here. I live in Tahoe now, and I hadn’t realized how close he was in the world until I saw your post! I would absolutely love to write to him to say hello, and also to ask a couple of very specific technical questions, but his site is currently down. I was wondering if you knew of any way to contact him? I totally understand if you wouldn’t want to give out his contact info, but perhaps there is a way you could pass mine along to him? It would mean the world!

I love old things, and the truth is I have more old things that are new-to-me than I need. The thing is, though, I buy them AND use them. Therein lies the delight!

Hi Lia – wow, what fun for you to do all this! I’ve taken classes with John – he is so sweet and an excellent teacher. His website was up this morning: http://johnmarshall.to Off the top of my head, I don’t remember his email address, but sign up for his newsletter and I am sure you will find it there. My last email address for him is john@johnmarshall.to. Hope this helps you out! He has online and in-person classes, though not sure if he is doing them now. I’ve taken a couple from him. Where in the Tahoe area are you? He’s outside of Willetts unless he’s moved.

I don’t know anything about sewing but, that is a neat old machine.

Thanks! I think sew too! (;-0